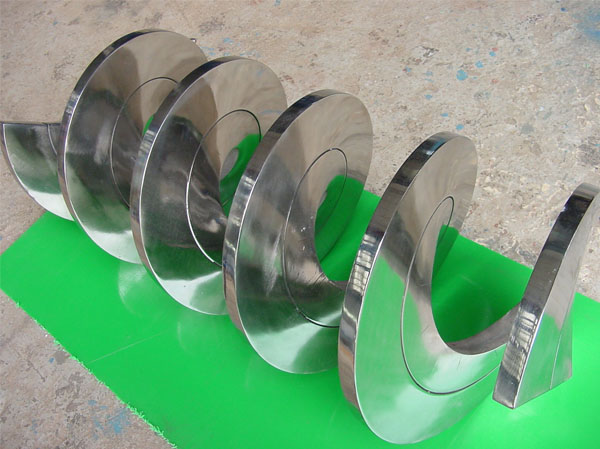

Shaftless Screw

Shaftless screw has the advantage in the non-clogging property. The shaftless design enables conveying dry, wet, viscous, adhesive, dusty or even abrasive material successfully. The system works under a closed lids, so there shall be no problems of dust, spills, or mal-odor. The screw can be made from special high tensile strength or stainless steel.

| Waste Handling | Industrial Handling |

| Screenings & Sludge Hospital wastes Slaughter house refuse Pulp & paper wastes Metal Chips Ashes |

All type of food processing Plastic granulate Chemicals and powder materials Pharmaceuticals industries Wood chips & Saw Dust Solid Fuel |

| Screw Size | Trough Width mm. | Screw Diameter | Q, m3/hr |

| 200 | 200 | 160 | 2.4 |

| 260 | 260 | 215 | 5.5 |

| 320 | 320 | 280 | 8.7 |

| 360 | 360 | 315 | 11.6 |

Flow in m3/hr, based in 36% trough fill and 30 rpm

Model GS is designed for washing and dewatering the grit while lifting it from hopper to a higher point of discharge. The influent shall be pumped into the classifier through piping positioned over the triangular hopper. The inclined grit screw conveyor washes and dewaters the grit while lifting it from the hopper to a higher point of discharge.

| Model GS260 | Model GS320 | |

| Flow capacity, m3/hr | 20-50 | 50-75 |

| Tank Surface, m2 | 2.3 | 3.0 |

| Tank Volume, m3 | 1.2 | 1.8 |

| Power, kW | 0.55 | 0.75 |

Model CY is an all purposes conveyor. The intake points as well as discharge ends can be made as many as required. The U-trough also works in inclination of up to 40 degree. In standard version, the conveyors are fitted with single spirals. For large quantities or steep inclination, the spiral blade height is increased by helical shaped inserts.

| Type | Capacity, m3/hr | Drive motor power,kW | ||

| a = o degree L = m n = 10 rpm |

a = 25 degree, L = 5 m n = 30 rpm |

a = o degree L =5 m n = 10 rpm |

a = 25 degree L = 5 m n = 30 rpm |

|

| CY200 | 1.0 | 1.0 | 0.75 | 1.1 |

| CY260 | 2.4 | 2.5 | 1.1 | 1.5 |

| CY320 | 5.5 | 5.5 | 2.2 | 3.0 |

| CY360 | 6.9 | 8.0 | 3.0 | 3.0 |

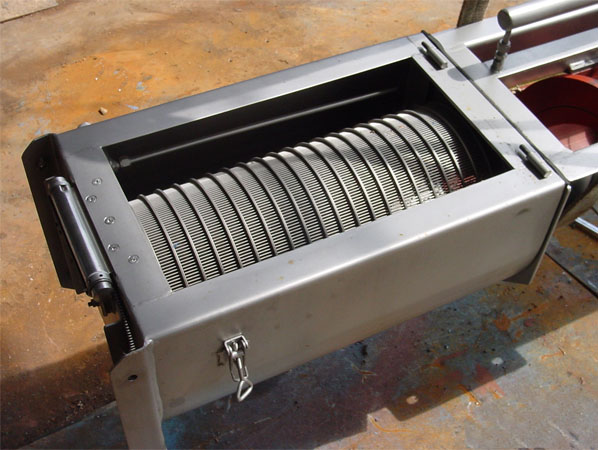

Model CP is designed for washing dewatering and compacting the trash while lifting it to a higher point of discharge. The spiral does not extend the full length of the compactor. The end of the spiral is enclosed with a sieve basket. This sieve basket serves as a compaction zone. The end flap valve is spring-tensioned and can be varied to adjust compaction degree.

| Model | Screw Diameter | Channel Width |

Flow,m3/hr,max. water level 460 mm. | |||

| Filtration | Conveying | Slot 1.0 | Slot 1.5 | Slot 2.0 | ||

| CP 260 | 215 | 215 | 300 | 36 | 45 | 54 |

| CP 320 | 320 | 215 | 400 | 80 | 100 | 120 |

| CP 360 | 360 | 215 | 500 | 144 | 167 | 190 |